The powerful R&D team and laboratory setup are the cornerstones of high-quality research and development.

Sanhua(Xinchang) R&D Center Laboratory

The Sanhua (Xinchang) R&D Center owns a state-level laboratory certified by CNAS, capable of conducting tests on behalf of third parties and issuing authoritative reports. It also has a metrology testing center that has passed GB/T19022 and ISO10012 certification, and is qualified for measuring instruments calibration and maintenance. The laboratory is equiped with over 300 testing devices, covering 21 professional testing fields and more than 1300 specific testing items. Among them are a lot of cutting edge equipments worldwide.

Enthalpy Difference Laboratory for AC & Heat Pump

The laboratory meets the standards of ARI 210-240, GB/T 17758-2010, ISO 5151 and JIS B8615, can be used to measure the cooling capacity, heating capacity, non-steady state heating capacity, power consumption COP and air volume of room air conditioners. The temperature control accuracy can reach +/-0.2℃.

Sanhua has established 12 enthalpy difference laboratories worldwide, capable of covering system testing requirements from 15-120KW. The highly automated control system can achieve automatic conversion under different test conditions, meaning we have the capability to test 24 hours a day.

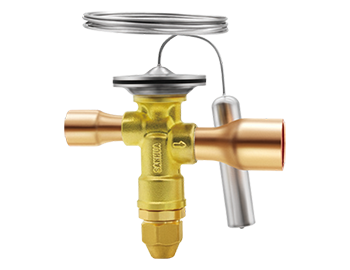

Case: Sanhua RFGF thermostatic expansion valve is a widely used product series in the North American air conditioning market, but when it was first introduced, it was limited by the lack of experimental resources for client-side matching performance testing, resulting in slow progress. In order to catch the last window phase before the system launch, we coordinated internal resources and achieved synchronous testing at 3 different laboratories in Houston, Hangzhou, and Xinchang, completing the matching of 5 systems in just 2 weeks, fully demonstrating the Chinese speed.

Laboratory for Cold Room System

The laboratory is designed based on 12 national and industry standards, built based on actual cold storage engineering, and equipped with world-leading measurement instruments. It is not only capable of testing cold storage systems but also individual components, including:

1) System cooling capacity, compressor cooling capacity, air cooler cooling capacity and condenser heat capacity

2) Heat exchanger temperature difference, coefficient and power consumption for air cooler and condenser

3) Defrosting design of the air cooler (observing the defrosting time and drainage situation)

4) Frost formation during the refrigeration process of the air cooler, indirectly reflecting the distribution situation

5) Compressor efficiency (difference between actual compressor cooling capacity and selection software display)

6) Lubrication oil content during system operation

7) The matching of various components in the system

The laboratory consists of 3 cold rooms of different sizes, with the largest capable of testing 125hp systems and able to test up to 4 evaporators in parallal. It is also equipped with a powerful outdoor environmental cooling system that can actively control the ambient temperature, providing year-round testing capabilities. The system design supports different evaporators, whether it is air cooler, aluminum tube bank or rapid freezing shelf, all of which can be adapted to.

Click to learn more about cold storage cold source project

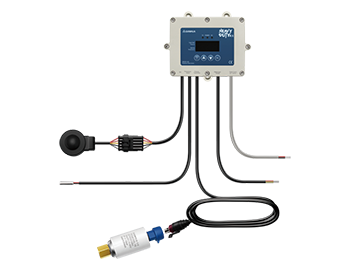

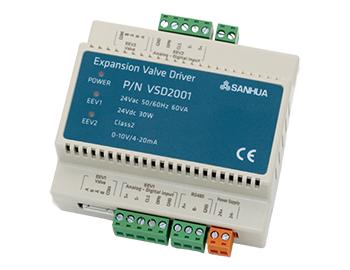

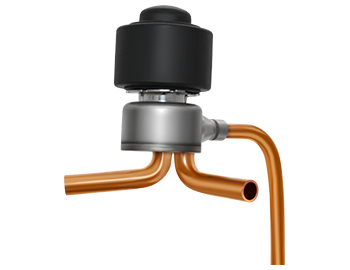

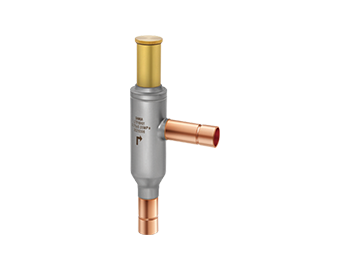

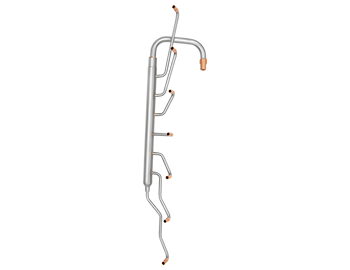

Expansion Valve Cooling Capacity Testing Bench

This testing equipment can test the cooling capacity of EEVs and TXVs under different evaporating and condensing temperatures, with the lowest evaporating temperature reaching -60℃. Through a large amount of actual test data, we can provide the capacity of expansion valves under any working condition and have integrated them into Sanhua Quickfinder selection software.

Brazed Plate Heat Exchanger Performance Testing Bench

Currently, Sanhua has 4 performance testing rooms with capacities of 30KW, 40KW, 80KW and 350KW, capable of meeting the testing requirements of BPHE for different capacities. These rooms can cover applications such as water/water (wall-mounted gas boiler, data center free cooling), refrigerant/refrigerant(economizer), water/refrigerant(condenser or evaporator).

The 40KW testing bench is an ATEX-proof laboratory that can test the performance of BPHE which is used for flammable refrigerants such as R290. The other testing rooms can meet the testing needs of A2 and A2L refrigerants.

The 350KW testing bench adopts an oil-free system, meaning that any refrigerant (except flammable refrigerants) can be replaced through refrigerant recovery.

The 80KW performance testing bench also has the ability of anti-freezing test, and through a large amount of test data, Sanhua has obtained the evaporating temperature at which the BPHEs get freezed, providing customers with freezing formation curves under different working conditions.

Click to learn more about Sanhua Plate Heat Exchanger technology

Anechoic Chamber (Noise Level)

Equipped with fully and semi-soundproof room, the inherent noise is below 16dB(A). The indoor temperature and humidity can be controlled, with the lowest temperature down to -40℃, allowing for the simulation of noise performance under the most realistic conditions. For example, products such as electronic expansion valves and drain pumps are installed indoors, consumer attention to noise is extremely high, and Sanhua continuously breaks through the low-noise level of our products.

Click to learn more about Sanhua silent electronic expansion valves and BLDC drain pumps

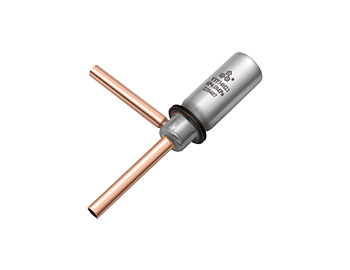

Filter Driers Testing Room

Designed and built according to American ARI/ANSI/ASHRAE standards, the room can test the flow capacity, filtering ability and dynamic water absorption of filter driers. The test data is showing that the water absorption performance of Sanhua filter driers is 20% higher than that of competitors, and the impurity filtering ability is 20~40% higher. It's worth mentioning that to ensure the formalization of testing, the impurity particles used for filtering capacity testing are strictly selected and imported from the desert in Arizona, USA.

Do you know how to select the filter driers ? Sanhua selection software Quickfinder

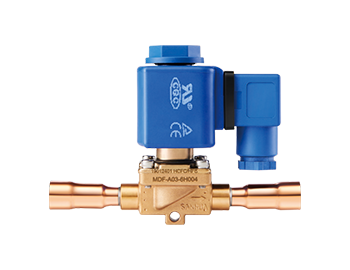

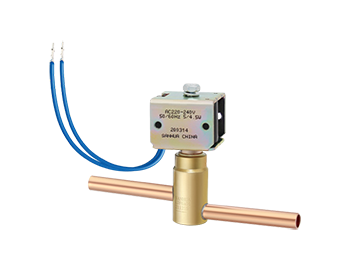

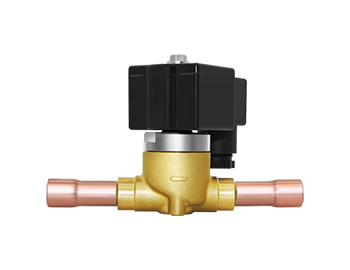

Electrical Safety Testing

We carry out numerous electrical performance and flame retardancy evaluation projects, such as grow wire, insulation, voltage resistance, leakage trace, etc. These projects are usually found in the laboratories of international third-party certification agencies, and thus Sanhua has also become a witness laboratory for TUV and UL. Meanwhile, with the application of A2L and A3 refrigerants, the evaluation of electrical safety is constantly being updated.

Click to learn more about Sanhua's solutions for A2L/A3 refrigerants

Industrial CT (X-ray)

It can scan the inside of the product 360 degrees without disassembling the product, effectively assisting in the root causeanalysis of failed product.

Chemical and Physical Analysis

One of the entire floor of the laboratory is equipped with various chemical and physical analysis instruments. It's worth mentioning that the ICP spectrometer has the ability to detect different elements and their proportions in substances, ultimately revealing the true nature of the substance, which is particularly helpful for the analysis of foreign matter in systems or valves. In short, all 72 elements in the periodic table can be detected.

Tops of the Sanhua Laboratories

The largest cooling system testing capacity: 125hp

The largest AC & heat pump testing capacity: 120KW

The largest BPHE performance testing capacity: 350KW

Maximum test pressure: 18MPa, meeting the durability test requirements of CO2 components

Maximum test connections: DN150@3.5MPa, meeting the durability test requirements of industrial refrigeration valves

Fastest temperature switching speed: Numerous environmental test chambers, capable of instantaneous switching between -60℃and 160℃, fastest to reach the stable target temperature of the tested product within 5 minutes.

Highest measurement accuracy: Axis measuring instrument: +/- 1 micron; Coordinate measuring instrument: +/-(4+5L/1000) micron; 3D blue light scanner: shape error: 3 micron, spherical error: 6 micron, capable of non-contact measurement, particularly helpful for the measurement of thermostatic expansion valve diaphrams (ultra-thin, contact measurement will destroy the diaphrams).

Other R&D Centers of Sanhua: Hangzhou; Cixi; Stuttgart, Germany; Detroit, USA; Houston, USA

Due to the distribution of R&D centers across various regions and time zones worldwide, 24-hour non-stop research and development can be ensured at Sanhua.