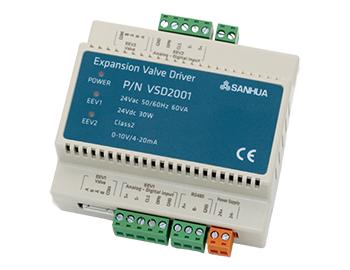

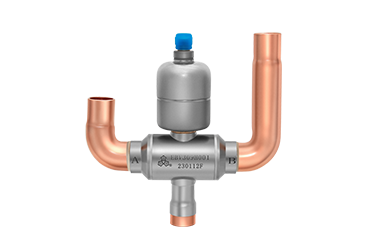

At Sanhua, we annually produce nearly 300 million units of components, with efficiency and quality in large-scale manufacturing being a source of pride for Sanhua. We are striving towards Industry 4.0, constructing an industry-leading intelligent park in our field.

Our highly automated production lines minimize the uncertainty of human operation, significantly enhancing product performance and quality consistency.

Intelligent logistics: Integration of Advanced Planning and Scheduling (APS) with Automated Guided Vehicle (AGV) Dispatch System (RCS), including batching plans, delivery and finished product storage. A single barcode enables end-to-end traceability.

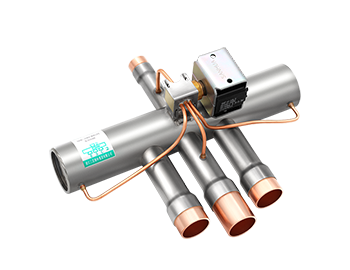

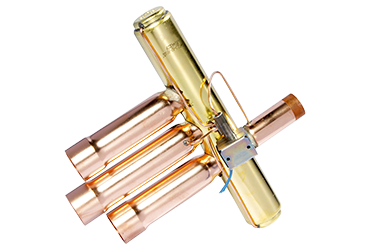

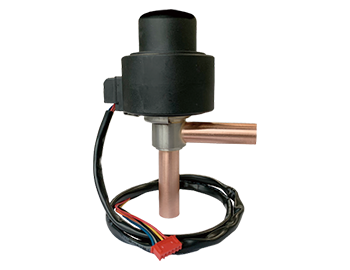

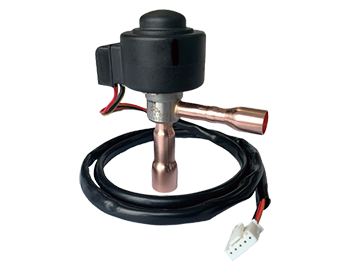

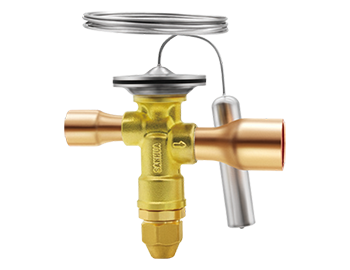

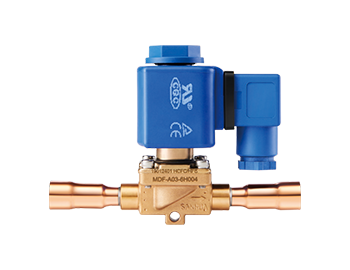

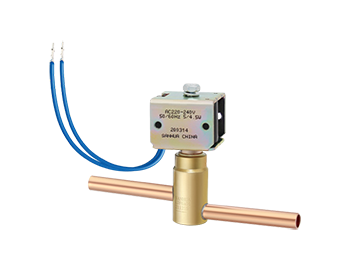

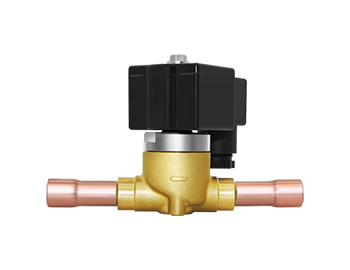

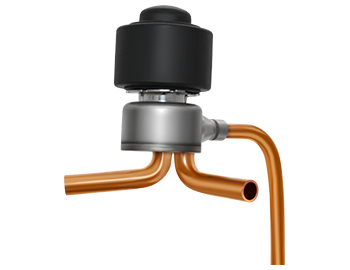

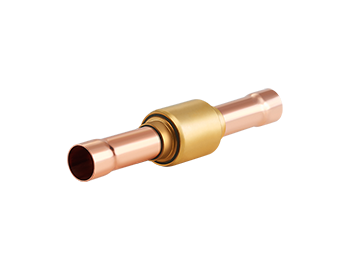

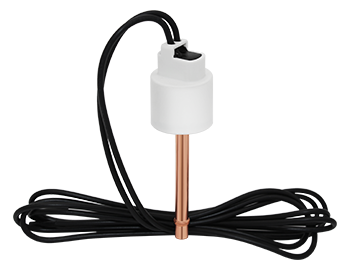

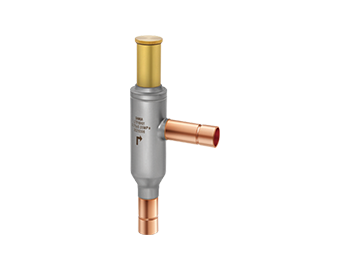

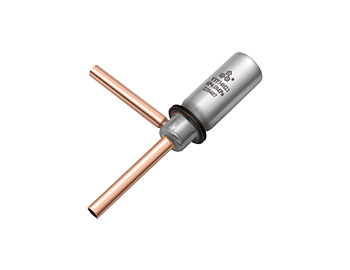

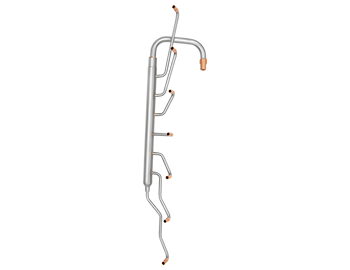

With our strong own R&D capabilities of equipments, we have completed of many fully automated production lines, including electronic expansion valves, thermostatic expansion valves and 4-way reversing valves, allowing for rapid capacity increase within the shortest time. Meanwhile, we continuously improve equipment efficiency through machine networking and energy management platforms.

Quality control: we actively implement KICCHIRI activities. KICCHIRI is a system that enhances execution capabilities of operators through clarifying correct worker states and standardizing operations, allowing team leaders to focus on on-site and abnormal situation management, which makes them become professional quality managers on production lines. Optimized work instructions offer great visualization, making it easy for even those with no prior experience with the process to understand.