1. Introduction to Key New Refrigerants

1.1 Refrigerant R32

Developed by Daikin, mainly used to replace R22 and R410A in air conditioning and heat pump applications, R32 can improve energy efficiency by about 10% compared to R22, and its GWP value is only 1/3 of R410A.

Previously, refrigerants were either non-flammable or flammable and explosive. R32 was considered as flammable and explosive, but through revised standards, the A2L (mid-flammability) refrigerant was born, with R32 being one of them. To promote R32, Daikin began gradually to disclose relevant patents since 2011.

1.2 Refrigerant R454B

Developed by Chemours(formerly DuPont), R454B is also a mid-flammable refrigerant, composed of 68.9% R32 and 31.1% R1234yf. Its GWP value is 466, and it is more compatible with existing R410A equipment design, requiring less or similar refrigerant charge. Currently, two major groups have formed in the medium and high temperature application, with Daikin promoting R32 and Carrier promoting R454B.

1.3 Refrigerant R290 (Propane)

A natural refrigerant with good thermodynamic properties, R290 can improve energy efficiency by about 10% compared to R22. Its GWP value is 3.3, and it is a natural hydrocarbon refrigerant that can be obtained directly from liquefied gas. The disadvantage is that it is flammable and explosive, and current regulations have clear limits on R290 charge for each country. R600a, which is also a natural refrigerant used in refrigerators, has the same flammable and explosive problem. However, since the charge in refrigerators is small, the danger is eliminated. But for air conditioning with higher capacity, we need more exploration by enterprises to solve this problem technically. On the other hand, R290 has smaller volumetric cooling capacity and sensitivity in pressure drop, so the cost of compressors and heat exchangers is higher than R410A systems, and the total cost of air conditioning is higher than R410A, which limits its promotion in Chinese market.

1.4 Refrigerant R744 (CO2)

A natural refrigerant as well, its GWP value is 1. CO2 has good advantages in producing hot water but there is energy efficiency limitations in refrigeration due to higher ambient temperature. CO2 can operate in subcritical or transcritical conditions. CO2 subcritical systems are usually cascade systems, with CO2 serving as the low-pressure side refrigerant, resulting in an overall higher GWP value and complex systems, and this was the only choice for high ambient temperature areas in the past. The efficiency of CO2 transcritical operation is limited by ambient temperature, and as the outside ambient temperature increases, a large amount of flash gas generated will reduce the system efficiency. However, technical progress is continuous, and the mainstream solution currently is to adopt injectors and parallel compressor technology.

The extremely high pressure brings high component costs, which largely limit CO2's promotion worldwide. Due to Europe's aggressive HFC phasing out target, there are no better choices, and from the perspective of life cycle return on investment, CO2 has been already better than HFC, and the price of HFC refrigerants is rising. Therefore, CO2 has been widely used in Europe.

Supermarkets, as relatively small systems, have easy access to transcritical application components. However, in industrial applications, due to the large size of the systems, large-diameter components are lack of availability, and the cost-limited industrial applications are still dominated by cascade systems. However, in recent years, large-diameter transcritical components have been continuously introduced, which is conducive to industrial applications of CO2 transcritical systems.

1.5 Refrigerant R717 (NH3)

NH3 has been used as a refrigerant for over a century due to its good thermodynamic properties, low cost, and availability. It is mainly used in industrial refrigeration and can be used alone or in a cascade with CO2.

NH3 has pungent odor and significant toxicity. If the concentration of NH3 in the air reaches 0.5%-0.6%, it can cause poisoning, and at a concentration of 11%~14%, it can be ignited when exposed to an open flame. When the concentration exceeds 16%, it can cause an explosion.

NH3 dissolves in water at any ratio, and icing doesn't occur even at low temperatures. However, it is difficult to dissolve in oil, so oil films are prone to form on the surface of the heat exchanger in NH3 refrigeration systems, affecting heat transfer. But since the density of oil is different from that of NH3, oil will accumulate at the bottom of the vessel, making it easier to separate.

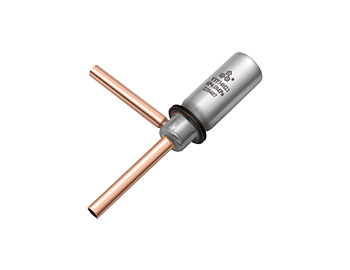

NH3 does not corrode steel, but it corrodes zinc, copper, and copper alloys (except for phosphor bronze) when it contains moisture. Therefore, copper and copper alloys are not used in NH3 refrigeration equipment, which is beneficial for the application of aluminum and stainless steel heat exchangers.

In Europe and United States, NH3 dominates in large scale cold storage and industrial refrigeration applications, but the usage in China is still subject to certain restrictions.

NH3 systems are typically pump circulation and flooded systems (with much higher energy efficiency than direct expansion systems). The charge can range from several tens of tons to over a hundred tons. It is an important issue currently on how to reduce the NH3 charge.

1.6 Refrigerant HFOs

Common HFOs include R152a, R1234yf, and R1234ze(E). R152a contains a certain amount of fluorine and is flammable, so it is rarely used alone but is often used in mixed refrigerants.

R1234yf was jointly developed by Honeywell and DuPont. As a single-component refrigerant, R1234yf has a GWP of 4 and an ODP of 0. The system performance is better than R134a. R1234yf is considered a promising alternative to current automotive refrigerants and has been accepted by automotive manufacturers worldwide. Although ASHRAE considers R1234yf to be slightly flammable (A2L refrigerant), years of testing by the SAE have shown that it will not ignite in the automotive air conditioning system environment.

R1234ze(E) has a GWP of 6. Although it also belongs to the A2L group, it is only flammable at temperature above 30°C.

Therefore, the EU standard EN 378 does not recognize R1234ze(E) as a ricky substance but rather as a fluid in Group 2 of the PED. This means that pipes and components with a nominal diameter <100mm do not require material traceability, while other flammable refrigerants require material traceability when the nominal diameter reaches 25mm.

R1234ze(E) has a lower volumetric cooling capacity than R134a or R1234yf by more than 20%, but its price is cheaper than R1234yf. The boiling point (-19°C) significantly limits its application in lower evaporation temperature applications. Therefore, it is best suited for liquid coolers and high evaporation temperature applications. It is considered more suitable for replacing R134a in screw and centrifugal chillers.

However, in recent years, research has pointed out that HFOs contain PFAS (perfluorinated alkyl sulfonic acid), a toxic chemical substance that can cause cancer and is difficult to decompose. Therefore, it may accumulate in the environment and human body. European countries are discussing a ban on PFAS, including HFOs, starting from 2025 under REACH regulations.

1.7 Other Mixed Refrigerants

Mixed refrigerants generally consist of two or more refrigerants mixed in different ratios, including R448A, R449A, R452A, R513a, R454B, R454C, and R455A etc. Most mixtures contain R32, HFOs, or HFC refrigerants, and the final flammability and GWP value depend on the proportion of their components. The higher the proportion of R32 or HFOs, the lower the GWP, the greater the volumetric cooling capacity, and the higher the discharge temperature, but the higher the flammability. For example, R454B is a Mid-flammable A2L refrigerant composed of 68.9% R32 and 31.1% R1234yf. Its GWP is 466.

One of the biggest challenges of the industry is developing a non-flammable R410A substitute with a low GWP. If the EU announces a ban on HFOs, mixed refrigerants containing HFOs will also be prohibited. Eventually, natural refrigerants R290 and R744 will become mainstream.

2. Refrigerant-related important policies and regulations

2.1 Montreal Protocol

To avoid further deterioration and damage to the Earth's ozone layer caused by fluorinated chlorinated hydrocarbons in industrial products, the United Nations continued the principles of the Vienna Convention on the Protection of the Ozone Layer signed in 1985. On September 16, 1987, the 26 member states of the UN signed the Environmental Protection Convention in Montreal, Canada. The convention came into effect on January 1, 1989.

2.2 Kyoto Protocol

The Kyoto Protocol was formulated at the third meeting of the UN framework Convention on Climate Change in Kyoto, Japan, in 1997. Its goal is to "stabilize the atmospheric concentration of greenhouse gases at an appropriate level to prevent harmful climate change from occurring."

2.3 Kigali Amendment

On October 15, 2016, the Kigali Amendment was passed at the 28th Conference of the Parties to the Montreal Protocol in Kigali, Rwanda. The amendment incorporates hydrofluorocarbons (HFCs) into the Montreal Protocol's control scope. HFCs are commonly used as alternatives to ozone-depleting substances (ODS), although they are not ODS themselves, they are greenhouse gases with high global warming potential (GWP). The Kigali Amendment sets reduction schedules for developed and developing countries.

On June 17, 2021, the Chinese Permanent Mission to the United Nations submitted the acceptance of the Kigali Amendment to the Secretary-General of the United Nations. The amendment will take effect in China on September 15, 2021.

In 2020, the United States passed the American Innovation and Competition Act (AIM), which actually established the country's emissions reduction plan for 2036 based on the requirements of the Kigali Amendment. In September 2022, the U.S. Senate approved the Kigali Amendment and officially joined it on October 31, officially participating in international cooperation on CO2 emissions reduction.

In summary, the Montreal Protocol limits high-ODP refrigerants, the Kyoto Protocol limits high-GWP refrigerants, and the Kigali Amendment provides a clear timeline.

Note:

Non A5-1 (Non A5, Early Start): Includes most non-Article 5 countries (developed countries) such as the United States, Japan, EU countries, and Australia;

Non A5-2 (Non A5, Later Start): Russia, Belarus, Kazakhstan, Tajikistan, Uzbekistan;

A5-1 (A5 First Group Countries): Most Article 5 countries, such as China, South Korea, Thailand, Brazil, etc.;

A5-2 (A5 Second Group Countries): Bahrain, India, Iran, Iraq, Kuwait, Oman, Pakistan, Qatar, Saudi Arabia, UAE.

2.4 EU F-Gas Regulation

This regulation represents a more aggressive reduction plan for the EU compared to the Kigali Amendment. It came into effect on January 1, 2015. The regulation promotes the reduction of HFC refrigerant use through quota systems and industry bans related to high GWP refrigerants from 2015 to 2030. The 2030 target is 21% of the baseline level. As a complementary measure to the phased reduction plan, regulations have been established for the prohibition of new equipment and retrofitting equipment using high GWP refrigerants.

The EU proposed legislative amendments in February 2022 to update the F-Gas Regulation (Regulation (EU) No 517/2014) released in 2015. The new draft is under discussion in the European Parliament and the European Commission.

In the air conditioning and heat pump industry, the commonly used refrigerants with GWP less than 150 are only R290 (3.3) and R454C (148). R454C is less competitive due to its higher price (contains 78.5% HFO-1234yf) and GWP near the limit. R290 can solve the GWP limit problem in one step and has high energy efficiency, conforming to the long-term requirements of energy saving and emission reduction in the EU. Therefore, it has become the mainstream solution.

European companies are promoting a GWP limit of 150 for all systems by 2030.

In the refrigeration industry, the commonly used refrigerants with GWP less than 150 are two types: R744 (1) and R290 (3.3). According to industry research, these two refrigerants will remain in the long term.

2.5 US SNAP

The US Environmental Protection Agency (EPA) established the Significant New Alternatives Policy (SNAP) program in 1989 as a tool for implementing the phase-out of ozone-depleting substances (ODS). The original purpose of the SNAP program was to achieve a safe and smooth transition during the phase-out of ozone-depleting substances. The SNAP mechanism accepts or ultimately prohibits the use of specific refrigerants in certain applications. However, from 2014 to 2016, it was also used to ban certain previously accepted high GWP HFCs.

In August 2017, the US Supreme Court rejected the HFC ban regulation. In July 2018, it was reported that 11 US states sued the EPA for "effectively repealing" the regulation prohibiting the use of HFC refrigerants in new equipment.

In 2020, the AIM bill was incorporated into the 2021 Consolidated Appropriations Act, requiring a 85% reduction in the production and consumption of HFCs by 2036.

In April 2021, the US EPA released the new SNAP 23 version, listing R448A, R449A, and R449B as acceptable refrigerants for retail food refrigeration equipment; listing R452B, R454A, R454B, R454C, and R457A as acceptable for new residential and light commercial air conditioning equipment; and R32 as acceptable for new residential and light commercial refrigeration and air conditioning equipment (R32 was previously acceptable, but only for room air conditioners with a built-in design).

Overall, in the US market, due to unclear federal guidelines, individual states have developed independent plans, with California leading the way. After the Biden administration took office, it has renewed climate change policies and aims to lead related strategies.

The California Air Resources Board (CARB) has already implemented an early reduction plan for HFCs, with regulations banning refrigerants with GWP higher than 750 starting from January 1, 2025. More states are following suit.

In 2022, Florida, Oregon, North Carolina, and Washington have updated their building codes to allow the use of A2L refrigerants in large-scale air conditioning and heat pump systems. The International Code Council (ICC) and the International Association of Plumbing and Mechanical Officials (IAPMO) are typically adopted in the US. ICC has updated its standards for using A2L refrigerants (in the 2024 edition), while IAPMO has not yet finalized its standards.

In 2022, the Environmental Protection Agency (EPA) approved a petition from AHRI and 23 air conditioning and component manufacturers, which requested that GWP 750 restrictions be implemented for new residential and commercial air conditioning equipment starting from January 1, 2025. VRF system manufacturers must comply with the new restrictions by the end of 2026. That is, R410A will be phased out starting in 2025.

UL 60335-2-40 has been updated to the third edition, incorporating safety assessments for A2L refrigerants into the standard.

2.6 China's HCFC and HFC Reduction Plan

China issued the "Green and Efficient Refrigeration Action Plan" in June 2019, pointing out that the reduction of HFCs will follow the plan agreed upon in the Montreal Protocol in October 2016. The overall phasing out plan for HCFC and HFC can be found in the figure below.

2.7 Japan's HFC Phasing Out Plan

In 2014, Japan implemented a comprehensive project to phase out HFCs. The project is a cyclical approach that aims to lower the GWP of the HFCs used and reduce system leaks during field operations (maintenance and recovery) and throughout the entire life cycle. Unlike the US or EU, the system does not directly prohibit or allocate specific quotas for use or import. Instead, it sets GWP target values for specific applications and combines identification management.

The Japanese High Pressure Gas Association has certified KHK for conducting extensive research on mid-flammable refrigerants and has proposed new requirements for air conditioning systems using mid-flammable and flammable refrigerants.

3. Trends of refrigerants used in different applications

3.1 Residential Air Conditioning and Heat Pumps

In the past, R22 and R410A were commonly used. Currently, the use of R32 is increasing year by year, as the risk of using mid-flammable refrigerants in room units is controllable due to the smaller charge volume.

The 7.0 version (IEC 60335-2-40 ED7) of the product safety standard for limiting the charge amount of propane (R290) and other flammable refrigerants in household air conditioners, heat pumps, and dehumidifiers, has been unanimously approved by the International Electrotechnical Commission (IEC). The maximum charge amount of R290 split-system air conditioners has been increased to 988 grams.

In the meantime, the maximum charge limit for a single circuit has been raised from 150g to 500g. Additionally, IEC 60335-2-40 ED7 also applies to independent window units, but some "careful design" is needed for this type of product to prevent flammable refrigerant leaks from outdoor components into the room.

Previously, R290 could only be used in Wall-mounted air conditioner with a capacity of 2hp or less. Now it can cover the entire range of wall-mounted A/C and even theoretically apply to floor-standing AC units. However, due to the higher system cost of R290, the commercial feasibility of replacing R32 is low, and regulatory push is needed.

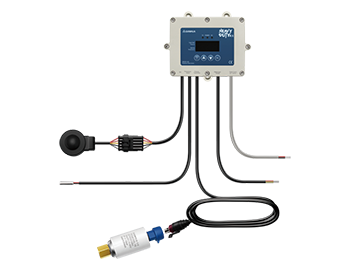

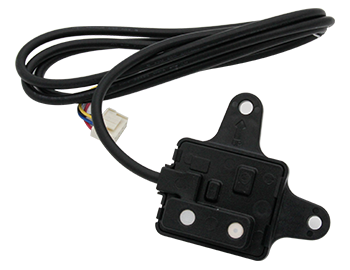

Sanhua's solution: Micro-channel heat exchangers can effectively reduce the charge amount of R290, making them the best choice for R290 applications. Additionally, sensors for detecting refrigerant leaks and mitigation board are necessary for R290 applications.

3.2 Unitary, VRF and Ground Source Heat Pumps(GSHPs)

Residential air conditioning in US is mostly in the form of Ductless Unitary. In the past, R22, R407C, and R410A were commonly used, but now R32 and R454B have become the two major choices. The US air conditioning market will switch to one of these two A2L refrigerants starting in 2025. Daikin and Goodman have opted for R32, while other brands have primarily chosen R454B, with a few units possibly using R32 or R454C.

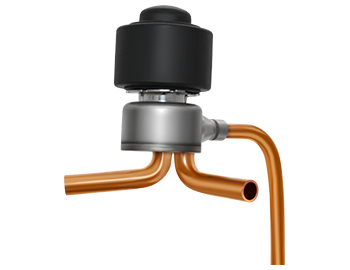

The latest version of UL60335-2-40 requires protective measures when A2L refrigerant leaks. Sanhua is providing A2L refrigerant leak sensors and Mitigation board as solutions. The UL standard may also require split-system units to be equipped with safety isolation valves (isolation valve).

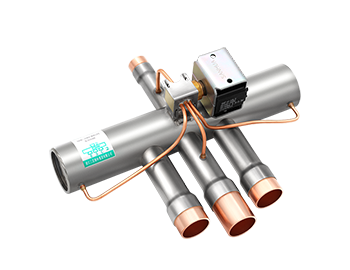

The Japan Refrigeration and Air Conditioning Industry Association released the JRAGL-16 mid-flammable refrigerant usage standard in August 2017. It requires that starting in 2025, R32 refrigerant in commercial air conditioners (mainly VRF) must be equipped with safety shut-off valves to prevent accidents caused by refrigerant leaks. Sanhua's solution is to use step motor-driven electric ball valves (EBV), which have been widely adopted in the market.

The US GSHPs are a type of Water To Air equipment. Currently, various brands are studying R454B as an alternative refrigerant. To reduce the charge amount of A2L refrigerants, heat exchanger technology is expected to be updated. Formerly, most outdoor heat exchange parts used shell and tube heat exchangers, but later brazed plate heat exchangers (BPHE) can be used. For indoor heat exchange parts, micro-channel heat exchangers (MCHE) can be used. As the evaporator during cooling and the condenser during heating, there is no need for defrosting.

3.3 Rooftop Air Conditioners

Mainly in the US market, R22 and R410A were commonly used in the past, and R32 and R454B are now being used as alternative solutions. The design is similar to that of American unitary, with Daikin/Goodman using R32, while other brands mainly using R454B, and a few units possibly using R32 or R454C.

3.4 Screw Chiller/Heat Pump System

Traditionally R22 and R410A were commonly used, but currently,European and American markets mainly use R32 and R454B as alternative refrigerants. For R32 water chillers (or heat pumps) in Europe,the design pressure is 49 bar (previously 45 bar for R410A),and the discharge temperature reaches 160 degrees Celsius during low-temperature heating applications. Parts on the discharge side must meet long-term 150 ℃ and short-term 160 ℃ requirements.

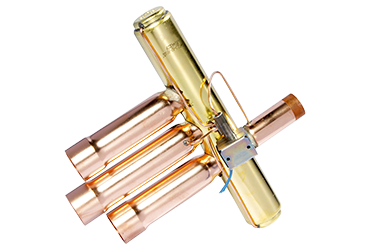

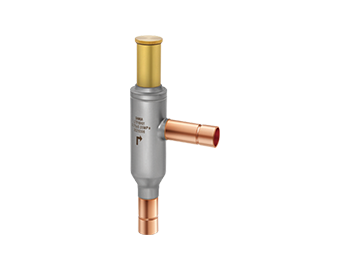

Sanhua has developed high-temperature resistant slides for 4-way reversing valves,as well as dedicated solutions of other products to be used as discharge sides,such as HDF pistion solenoid valves,RBV ball valves and CCV magnetic check valves. These solutions can meet the high-temperature and high-pressure requirements. In other system positions,there is no high-temperature requirement,but it is still necessary to meet the 49 bar design pressure.

3.5 Screw and Centrifugal Chillers

R134a and R123 were commonly used in the past, and on screw system the current alternatives to R134a are R1234ze(E) and R513A. On centrifugal chillers the alternative to R123 is R1233zd.

Although R1234ze(E) is an A2L refrigerant, it is actually only flammable above 30°C. Therefore the standard EN 378 does not recognize R1234ze(E) as a risky substance, but as a PED group 2 fluid. This means that pipes and components up to 100mm nominal diameter do not require material traceability, whereas other flammable refrigerants require material traceability up to 25mm, which is particularly critical for screw and centrifugal units with large pipe diameters. But if HFOs are banned in the EU by 2025, there are no good alternatives so far.

3.6 Heat Pump Water Heater

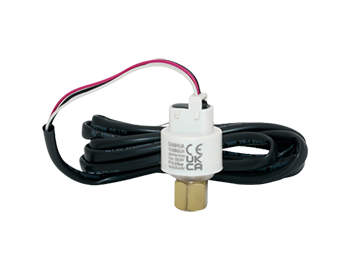

In the past, R134a was commonly used, the European market is now mainly for R513a and R290 attempts, SANHUA is providing the industry with micro-channel evaporator (indoor installation models), micro-channel belt heat exchanger (water tank), RFGC stainless steel (hermetic TXV) and pressure switches, etc. The Japanese market is mainly going with CO2, which has been used for many years through government incentive, using CO2 transcritical systems with a maximum operating pressure of 150bar and a MOPD of 100bar.

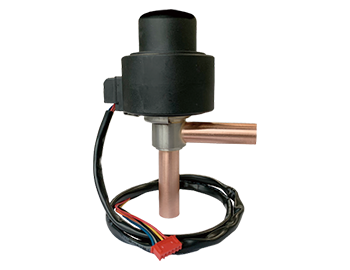

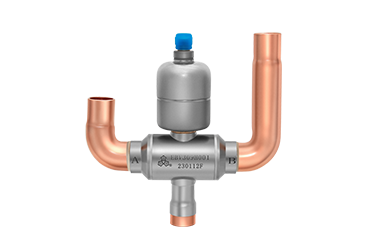

The SANHUA DPF(R) series of EEV is a popular solution for CO2 transcritical systems with a maximum operating pressure of 150 bar and a MOPD of 100 bar.

3.7 Heat Pump Heating

Traditionally,R410A was commonly used,but European mainstream brands have now focused on R290. Although R32 will be phased out only by 2027,most European brands have chosen to switch to R290 right now,which can solve the GWP issue in one step and offer high energy efficiency,in line with the EU's long-term energy saving and emission reduction requirements. R290 has become the mainstream solution.

European manufacturers have stopped developing new products using R32, and R32 machines will mainly be produced overseas (in countries like China and South Korea). Some European manufacturers have chosen R454C as a transitional solution before the R290 regulations were clear. R454C has a GWP below 150, making it a potential option, but its cost is relatively high.

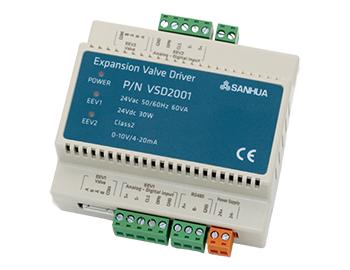

Sanhua's solution: For European R290 heat pumps, Sanhua has invested a dedicated ATEX-proof performance testing platform, focusing on optimizing the R290 BPHE performance. Sanhua's SD2 series of variable frequency drivers from Sanhua Leaderway already has a complete product line, and its products comply with EN60335-1 (related to drivers), EN60335-2-34 (related to compressors), and EN60335-2-40 (related to air conditioning and heat pumps) standards, making them suitable for A3 refrigerants.

In terms of valves, electrical products need to meet EN60335-2-24 (clause 22.110), EN60335-2-89 (clause 22.109), and EN60335-2-24 (clauses 22.116 , 22.117 and Appendix BB), as well as pass the enhanced 850°C glow wire test. Currently, 4-way valves, solenoid valves, EEVs, pressure transmitters, and pressure switches have all obtained relevant 3rd party certifications (TUV).

3.8 Light Commercial Refrigeration Equipment

This category includes refrigeranted display cases, commercial ice machines, ice cream machines, kitchen refrigerators, and other plug-in devices with small capacities. Historically, R134a, R22, and R404A were commonly used, but R290 will dominate the market in the future. In the European market, the charge limit for R290 has been increased to 500g, eliminating the need for multiple-circuits ystems(150g each), making system design more flexible and convenient.

In the transition phase of replacing HCFCs in China, some R410A (with improved energy efficiency in high-temperature applications) was adopted, and the trend of using R290 has not yet formed. There is also a lack of large-capacity R290 compressors, so light commercial refrigeration equipment with a charge over 150g has not yet been developed.

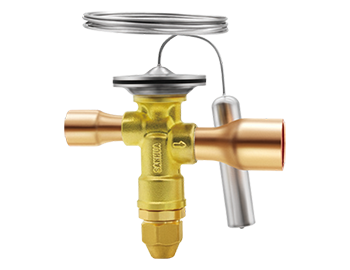

Sanhua's solution: Micro-channel condensers, RFGB and RFGC series TXVs, and smaller-capacity dry filters to reduce the charge volume, as well as the DTG-M02 series specifically developed for small R290 refrigeration equipment.

Please note that there are also relatively large plug-in refrigeration equipment (5-10KW) that cannot use R290 (charge volume exceeds 500g per circuit), so it will temporarily consider using R454C (GWP=148) or R455A (GWP=148), both of which belong to A2L refrigerants.

3.9 Condensing units, Compressor Racks

In the past, R22, R404A, and R134a were commonly used. During the transition stage, R448A/R449A/R452A/R454C/R455A were used. R448A/R449A/R452A still have high GWP values and are expected to be phased out soon. R454C and R455A have a GWP of 148, which meets medium and long-term requirements but belong to A2L refrigerants. European mainstream companies have launched R454C condensing units (mainly for small and medium-sized cold stores).

Sanhua's pressure control has been redesigned to meet the requirements of A2L refrigerants. For condensers, micro-channel heat exchangers are good alternatives, which have been widely accepted in the European market.

Panasonic's CO2 condensing units have sparked a wave of CO2 condensing units in Europe, and European brands have begun to launch CO2 transcritical condensing units, mainly used in small cold room and convenience stores, with relatively simple systems.

Sanhua's solution: Micro-channel CO2 gas coolers, variable frequency driver, and EEVs. Sanhua is committed to reducing system costs to promote the widespread use of CO2 in small cold room and convenience stores.

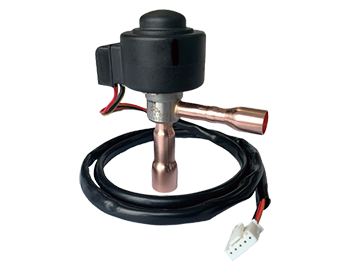

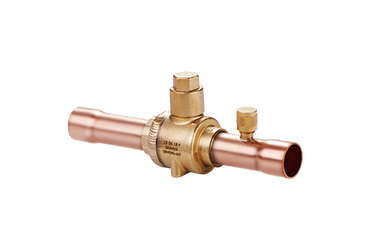

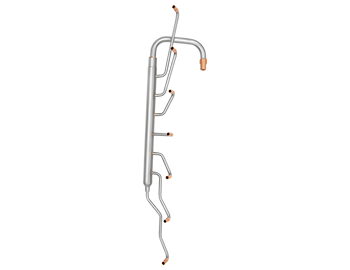

Racks are mainly used in large supermarkets. In Europe, CO2 is already dominant, and the US market is also experiencing rapid growth in CO2 units. Currently, on the rack system side, Sanhua has launched pressure sensors, ball valves, check valves and service valves(gauge valves), and the design pressure of EEVs (display cases) requires 90bar. LPF-T (stepper motor) and PEV (PWM type) are 2 EEV families of Sanhua that been introduced to the market.

3.10 Semi plug-in Display Cabinets

Usually designed as waterloop system, due to the connection of water pipes among cabinets, the refrigerant charge is significantly reduced compared to remote display cases, allowing the use of R290 refrigerant. Sanhua's solution includes BPHE(condensers), electric water ball valves, EEVs, dry filters, sight glasses, pressure sensors, pressure switches, and variable frequency drivers.

In the choice of fixed-frequency vs. variable-frequency, Chinese markets primarily use air curtain cabinets, which require frequent stop-and-defrosting cycles, making variable frequency difficult to implement. In Europe, glass-door cabinets are more common, using electric defrosting, which significantly improves variable frequency performance.

3.11 Industrial Refrigeration

Mainly composed of NH3, CO2, or NH3/CO2 cascades, R717 (NH3) dominates the large-scale cold storage and industrial refrigeration field in Europe and United States. In China, due to multiple ammonia accidents, NH3 application has been greatly restricted, except in the chemical industry. Many large-scale cold rooms have returned to using fluorinated refrigerants (mainly R507A) instead, which has partially driven the adoption of CO2 in the industrial field. Currently, experts are actively promoting the safe use of NH3, and there is still a chance for NH3 to return to industrial refrigeration in the Chinese market