We divide the cold storage into 6 major sections: the first is the pannels, the second is the compressor, the third is the refrigeration vessels, the fourth are evaporator and condenser (air cooler condenser), the fifth is the flow control parts, and the sixth is the electronic system. The cold storage refrigeration refers to the 2rd to 6th sections (excluding the pannels). Among the 6 major sections, there have been numerous tests, and the result shows that there is not much difference between the products of Chinese top brands and those of European and American brands.

For example: if a cold storage from a good European brand can score 90 points, then our Chinese first-class brands can score 80 points; if the compressor of Europe brand scores 90 points, the excellent Chinese brands can score 70 points; the same goes for the refrigeration vessels, and the flow control parts and electronics systems are almost identical to those in Europe. With equivalent quality and a competitive price, Chinese first-class brands have a high cost-performance ratio. Among these 6 parts, only the air cooler, Chinese and foreign first-class brands have a very big gap.However, we should not be discouraged, as there are already more than 10 manufacturers striving to catch up. We believe that soon we will see the market led by capacity based air cooler that we have been advocating, all of which are air cooler with capacity data. Whether there is a gap or not, the data speaks for itself, which is a big progress.

How did this progress come about? It is based on our '3x Shares and 1x Manufacturing'.

First: Shared technology. Everyone knows that our industry lacks technology, so how can we change the status quo of lacking technology in our industry?It is to share technology.We have a strong theoretical and practical technical team, which can push the products forward. In particular, our bottle neck: T&F heat exchangers. Through years of cooperation with professors and experts from University, we have basically conquered the core technology of T&F heat exchangers. Currently, compared with European top-ranking air coolers, we only lack manufacturing experience, as these are manufacturing companies with 80 or 90 years of experience. Their experience is indeed rich, but we don't lag behind in terms of principles, and we only lack the polishing of the manufacturing part and personnel training.

There are 5 key elements for a product to be successful: people, machine, material, method, and environment. The first element is people. Even with good design and good drawings, if there are no good workers, it is still impossible to produce high-quality products. The machine refers to the equipment, and our current equipment is not bad. The material, and the heat exchangers are made of copper. Actually, the European and American manufacturers choose the same suppliers as us, so there is no difference. The method refers to the production method, and we have technology but also ensure that the production method is correct. The environment refers to the factory environment, and we need to visit the site to check the site management. If the site is dirty and messy, the product will definitely not be good. With these 5 elements, there should be no problem in producing the product.

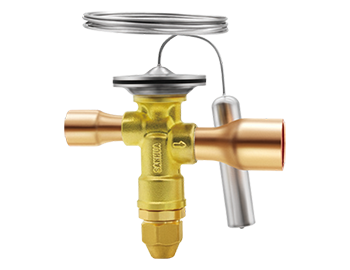

In fact, in the 'cold storage refrigeration system' sector, we have many pioneers, all of which come from our air conditioning industry. There are devices called Intelligent Cold Storage Systems, but they all share one thing in common: they follow air conditioning technology. The product of the air conditioning technology has a obvious characteristic, which is completely sharing the mold of the outdoor unit of the air conditioning. In this way, the refrigeration design of the cold storage facility is not entirely unusable, but it does have its shortcomings. First of all, the expansion valve should not be placed on the outdoor unit, and then the fin spacing of the air cooler is 4.5mm, whether it is 0 cold storage or -18 degree C cold storage. Therefore, it may be acceptable to use this design in some stable scenarios, but for more complex, more frequent warehouse operations, or high humidity cold storage, it cannot achieve the satisfaction of the owners.

There are differences in products technology roadmap between air conditioning and cold storage, and understanding the principles can help you make better choices. The Cold Storage Technology Alliance(CSTA) has introduced the "Integrated Cold Storage Refrigeration Technology Manuel," which includes a comprehensive table of refrigeration capacities for integrated cold storage refrigeration system. Designing, selecting, and constructing equipment capacities according to the manual can achieve the desired results. This is based on the entire nation's requirements.

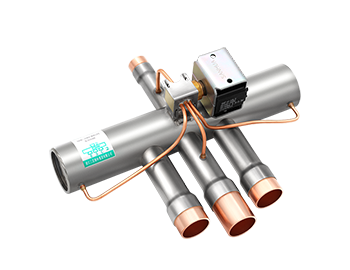

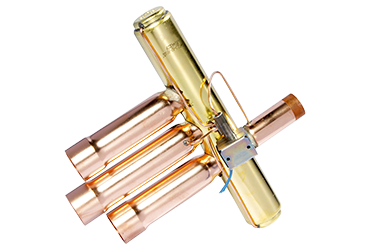

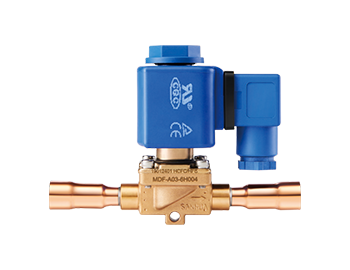

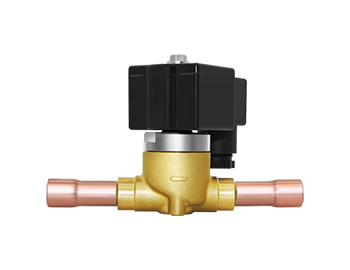

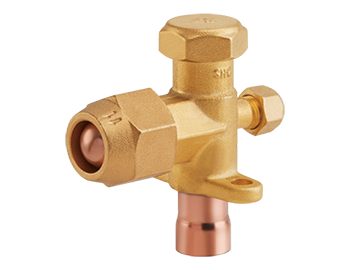

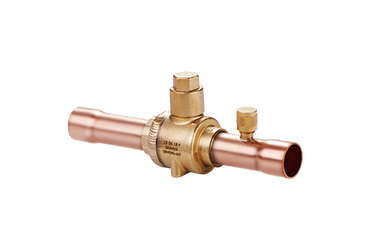

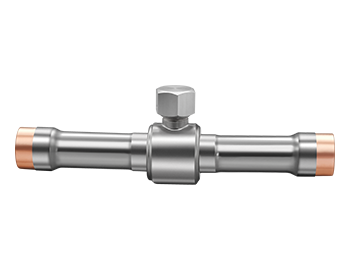

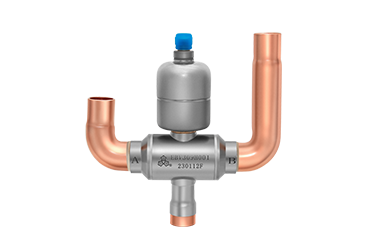

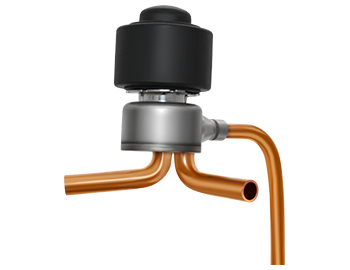

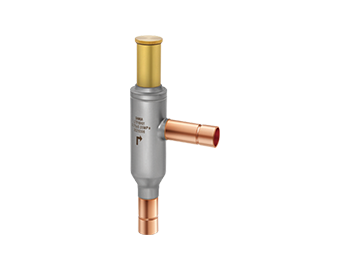

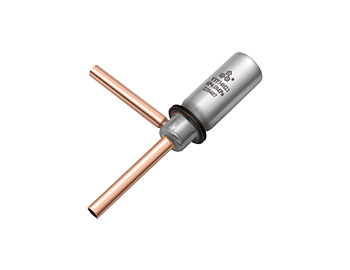

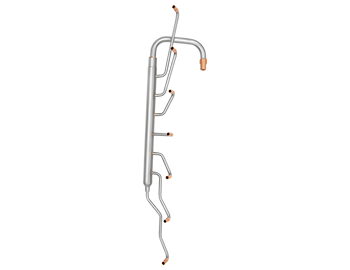

The outdoor units designed by us are structurally different from those designed by the air conditioning followers. The layout of the piping and condenser is arranged vertically, unlike the horizontal arrangement in air conditioning, allowing the machine to be opened for maintenance and inspection without affecting operation. In the cold storage refrigeration system, the liquid receiver volume is crucial. Whether it is hot gas defrosting or electric defrosting, it is energy-saving to recover the refrigerant in the evaporator before defrosting. But if there is not a sufficient volume of a liquid receiver, you can only let the low temperature refrigerant stay in the evaporator when you shut down the system, and the low temperature refrigerant in the evaporator is directly heated during defrosting, which wastes heat and prolongs the defrosting time. Standard the hot gas defrosting or electric defrosting of cold storage defrosting methods always recover the low-temperature refrigerant in the evaporator before defrosting(pump down), ensuring good performance and high efficiency while saving electricity. Another point to emphasize is the use of an suction accumulator with intercooler. When the ambient temperature higher than 35℃, the subcooling of the ordinary cold storage unit condenser dropped to 0℃. The reason for using a accumulator with intercooler is that it can generate subcooling inside the accumulator during summer, thus improving the system's efficiency. It's also essential to integrate the filter, solenoid valve, and expansion valve into the air cooler and close to each other.

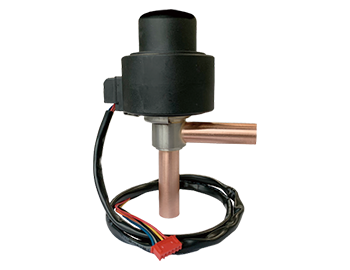

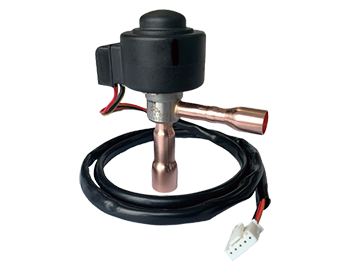

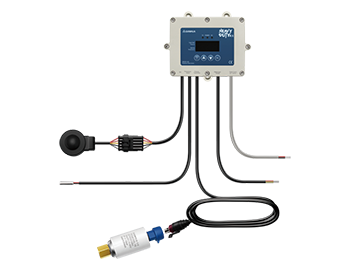

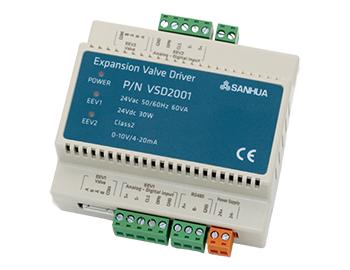

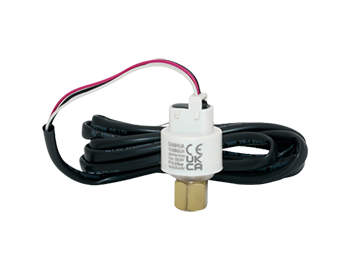

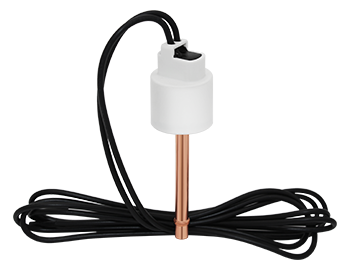

Our solution features another innovation: fully digital operation, replacing the pressure gauge with a pressure sensor. Condenser fan adjustment at winter time is crucial, but not every lower condenser temperature means a better refrigeration system. The winter condensing temperature should not be lower than 35°C and higher than 40°C. based on this, we need to control the condenser fan: Control the saturation pressure corresponding to 35 ° C and 40 ° C, and this pressure range will operate automatically. With a pressure sensor, we solve the data transmission issue but also control the condenser fan's operation and achieve better accuracy than pressure gauge. All data is integrated into a display, allowing users to monitor equipment operation, temperature, pressure, and current on the screen. This is what we call digitalization. The accuracy of the Sanhua pressure sensor is leading globally, and its consistent high cost-performance ratio makes comprehensive digitalization in the cold storage industry possible.

There are 3 volumes of the 'Integrated Cold Storage Refrigeration Technology Manual', which can solve the usage of all cold storages below 20,000 m³. The manual includes 3D modeling diagrams, equipment diagrams from 3 to 40hp, and various related parameters. Our newly developed electronic system is necessary for interconnected cold storages, which can reduce on-site services.

Second: Shared laboratories. Since the establishment of this project, we have invested 3 laboratories in Zhejiang Province, China. The Sanhua Commercial Laboratory can simulate the actual situation of cold storage to complete the full range of tests from 2 to 125hp, which is currently the largest testing range in the country.

This laboratory can achieve fully simulated engineering-level test scenarios, where environmental temperature, cooling temperature, humidity, and other factors can be matched according to actual usage conditions. Moreover, the testing function is powerful. The test results of the cold storage system include system refrigeration capacity, compressor capacity, air cooler capacity, and condenser capacity; the heat exchange temperature difference, heat exchange coefficient, and power consumption of the air cooler and condenser; testing the rationality of electric defrosting design in air cooler; frosting conditions of air cooler during refrigeration; testing the oil content in the refrigerant during system operation; and testing the efficiency of the compressor and the matching degree of various parts under working conditions. Although the construction cost of the laboratory is high, the higher cost is actually in its operation. The significance of shared laboratories enable the small and medium-sized cold storage system manufacturers to focus on production and manufacturing, and to minimize testing costs while obtaining all the data.

Third: Shared supply chain. By ensuring product quality and performance, we also need to control costs by reducing supply chain costs through 'Centralized procurement' and 'Mass production'. There is a precondition for shared supply chain: Let professionals do professional jobs. All of our suppliers are professional in their job: Professional condenser factories produce capacity based condensers; Sheet metal factories produce chassis; Pipe factories make pipes; Even the evaporator and condenser pipes have professional manufacturers. Sanhua provides a large number of stainless steel pipe solutions for the industry, which is very good in terms of efficiency, quality, and cost. We have a professional platform to receive and process orders.

Fourth: The Unified Workshop, also known as '1x Manufacturing', consists of 3 types of CSTA members: 1. Part manufacturers, 2. Final assembly workshops, 3. Cold storage contractors/installers.

The 6 major part manufacturers are referred to as part manufacturers. With previous shared technology, shared laboratories, and shared supply chains, they go for final assembly to meet the needs of local contractor, which are defined as final assembly workshops. The final assembly workshop is responsible for the integrated cold storage refrigertion system, with unified production processes, unified service standards, and a reasonable sales area. Cold storage contractor carry manuals to negotiate with owners, receiving projects, and are responsible for installation and after-sales services.