No matter temperature difference or data, what we talk about is all attributed to previous experience. However, completely experience-based things have gradually failed to meet the requirements of modern cold storage construction and usage. Therefore, we introduce a project based on the digitalization background of cold storage refrigeration systems: Integrated Cold Storage Refrigeration System.

- Cold storage size classification standards

The latest national standard has divided cold storages into large, medium and small sizes. Many people often claim to be involved in the construction of small cold storages, but the actual cold storage size is not small, because those with a capacity of less than 5,000m³ are called small cold storages. The scope of the cold storage has been clearly divided in the standard: anything below 5,000m³ is considered a small cold storage; between 5,000m³ and 20,000m³ is considered a medium-sized cold storage; and above 20,000m³ is considered a large cold storage. This is a standard based on the volume of the cold storage. In the new standard, it also divides the refrigeration system: systems with a theoretical displacement capacity of less than 500m³/h are considered small systems, between 500m³/h and 5,000m³/h are considered medium-sized systems, and above 5,000m³/h are considered large systems. After dividing large, medium and small sizes in the standard, we can discuss technology with preconditions. Any data is based on preconditions, and without them, it is impossible to discuss data.

- Is a medium & small cold storage a project or a product?

In our cold storage industry, with increasing labor shortage and high cost, we face a huge challenge: there is a lack of personnel, especially those who are willing to go to the construction site for installation. The slow development of our cold storage industry is closely related to the talent issue. Nowadays, consumers in China have the brand awareness, and we tend to buy better quality products. For example, when it comes to VRF air conditioners, we can choose Haier, Midea, Gree and Daikin; when it comes to commercial refrigerators, we can choose Hisense, Xingxing and Aucma. We buy branded products because we believe that the quality won't be too bad when we bring them home. However, when it comes to purchasing a cold storage, cold storage buyers don't have a specific brand to choose from. They can only seek contractors, and once they find an contractor, the contractor will solve the problem of a cold storage product in the form of a project.

Large cold storage is definitely a project due to its customized requirements. However, for small and medium-sized cold storages, especially those with a capacity of less than 5,000 m³, it's a challenging issue whether it's considered a project or a product with labor shortage and high cost. This is a sharp question for current cold storage suppliers. When negotiating with owner about cold storages, it's usually a marketing without physical products, as it's impossible to carry a cold storage for discussion. In this case, we can only treat it as an engineering cold storage and rely on oral description. This may lead to a discrepancy between the owner's expectations and the actual product we deliver after the cold storage is completed. At this point, dissatisfaction with use may arise, causing difficulties in payment and settlement.

- Cold Storage Industry vs Air Conditioning Industry

In fact, refrigeration industry has a good benchmark: Air conditioning. However, why is the development level of our cold storage industry far lower than that of the air conditioning industry? We need to understand the advantage of the air conditioning industry, which is actually one thing: They have talents. Every year, there are thousands of graduates majoring in refrigeration, including undergraduates and postgraduates in China. Where have they gone? about 90% of them have gone to the air conditioning industry. The remaining 10% may even come to refrigerated industry, but they have gone to large-scale industrial refrigeration companies. Very few of them actually end up in our cold storage engineering industry or small and medium-sized cold storage equipment manufacturing industry.

The lack of talent in the industry means there is certainly no technology. based on the presence of talent and technology, the large-scale enterprise structure, and the strong standardization of products, the air conditioning industry has developed particularly well. The disadvantage of the cold storage industry is the lack of talent. The lack of talent means a lack of technology; Small enterprise scale, small-scale non-standard production, leading to poor product performance. This is why the two industries differ:Cold storage industry's development is slow, reliability is poor and the technology is backward.

- Mission of the Cold Storage Technology Alliance

How can we change the situation with such a serious shortcoming?

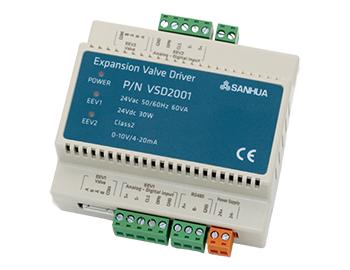

In order to address the current situation of small and medium-sized cold storage facilities lacking talent, technology, and branding, and suffering from poor manufacturing practices, since 2021, Sanhua, together with some cold storage parts manufacturers to form the Cold Storage Technology Alliance(CSTA), and the mission is to promote the digitalization of the cold storage refrigeration systems. This requires that the selection, design and matching of our various parts should be based on data. In fact, advanced European and American brands have comprehensive data for each part, but most Chinese brands have products without data. This is definitely not sustainable, and someone needs to drive this change. Therefore, CSTA focuses on doing the following 3 things:

1. Promoting the digitalization of the cold storage refrigeration systems;

2. Changing the current situation of 'having products but no data' in cold storage equipment industry;

3. Improving the energy efficiency of cold storage refrigeration systems and reducing its failure rate.

- How to define the future of cold storage? We summarize it as '4x standardization'

First of all, Digitalization of refrigeration systems. After the entire system is designed, the refrigeration capacity of the operating system, not the refrigeration capacity of the compressor, varies according to different technology and system configuration. For example, a 5hp compressor with technology will yield a higher cooling capacity, while the same 5hp compressor without technology will yield a lower cooling capacity. This is the refrigeration system data standardization.

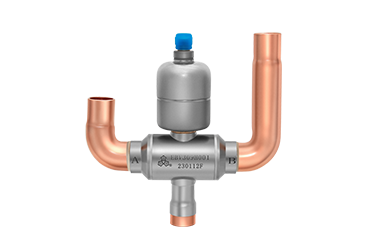

Second, to address the current challenges of labor shortages and high costs, we aim to minimize on-site construction costs for cold storage projects. We call this Pre-assembled & tested of cold storage and strive to complete 80-90% of the work in the factory. Cold storage contractors only need to provide on-site assembly, debugging, and maintenance services, improving labor efficiency and reducing costs.

The third point is reflected in technology, and puts forward a goal for our Integrated cold storage: Reduced refrigerant charging. This seemingly simple task is not straightforward. If the efficiency of the refrigeration system is low, and the evaporator, condenser, and pipe design are unreasonable, the refrigerant charging will necessarily be high. Some community logistics cold storages use only 100kg of ammonia for a 3,000-ton cold storage. Therefore, the issue is not the danger of ammonia itself but the excessive refrigerant charging. The technical level of a refrigeration system can be fully demonstrated by the refrigerant charging.

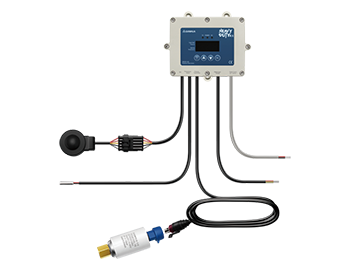

Fourth, we require Networked cold storage management. Our current high labor and transportation costs make it untenable to visit construction sites daily. Therefore, we need network standardization by monitoring the operating conditions on site through the IoT, detecting and solving problems early, and reducing maintenance costs.

By promoting these' 4x cold storage transformation' we can essentially solve the efficiency and stability issues of our current cold storage refrigeration systems.