With the start of Sanhua's technical roadshow about the cold storage refrigeration system solution, the design concept of integrated cold storage system has attracted much attention. Many people argue that this is the future of small and medium-sized cold storages, but the underlying logic behind it is not a sophisticated theory, but just temperature difference. However, before that, many people mixed "temperature" and "temperature difference," which could lead to a huge mistake. Today, let's talk about cold storage temperature difference.

Knowledge 1: The Relationship between Cold Storage Temperature Difference and Cold Storage Load Calculation

You may heard from many owner of cold room, who often say, 'I want a cold storage with a certain temperature, size, and storing certain items,' it has long been believed that the first thing to consider when building a cold storage is temperature. Perhaps some people will ask, 'Why do we need a concept of temperature difference for a cold storage? Isn't it right to start a cold storage with temperature ?'

Although the first step in discussing a cold storage with the owner is temperature, the designed temperature actually involves another work: Cold Storage Load Calculation. This involves deeply understanding the amount of heat inside the cold storage through calculation. In fact, the cooling capacity refers to the ability to exchange the heat inside the cold storage.

There are 5 main sources of heat in a cold storage: heat transfer from the maintenance structure (Q1), cargo heat (Q2), heat exchange ventilation (Q3)(Q3 is not applicable to every cold storage), motor operation heat (Q4), and operational heat (Q5). It should be noted that even with the same volume, the 5 heat sources may not be completely identical. Therefore, we cannot rely on experience that a the 2000m³ cold storage will always equip with the same devices as before.

There are 5 heat sources affecting the cold storage load calculation, but there are 14 factors that affect these 5 heat sources. These factors include: 1) Construction location, 2) Cold storage size, 3) Thermal insulation materials, 4) Storage temperature, 5) Refrigerated items, 6) Packaging materials, 7) Wind protection facilities in the storage, 8) Ventilation and overhead facilities in the ground, 9) Daily purchase volume, 10) Incoming temperature, 11) Evaporator type of the cold storage, 12) Load of other equipment inside the storage, 13) Presence of air curtains or soft door curtains, 14) Daily operating time of the refrigeration machine. Among them, the key factor is the construction location, the same two cold storages, one is built in the north and the other in the south, the heat load is definitely different. Secondly, the daily incoming volume, if the owner is not clear, then we can refer to the daily incoming volume written on national standard (not be less than 8%).As well as the incoming temperature, whether the goods have pre-cooling should also be clear.

According to the cold storage load calculation, we can determine the 'cooling equipment load' and 'mechanical load'. The cooling equipment load refers to the load of the evaporator, while the mechanical load refers to the load of the compressor. This provides direction for the selection of two major parts in refrigeration. However, the values of both the compressor and evaporator vary under different working conditions. How to accurately select the compressor and evaporator under variable conditions? This involves the concept of 'temperature difference'. And we say: Without setting a temperature difference, it is not possible to reasonably select the compressor and evaporator.

Knowledge 2: What is cold storage temperature difference?

It refers to the temperature difference between the evaporating temperature and the room temperature. How is this temperature difference determined? The type of storage items in the cold storage determines the relative humidity, and the ideal relative humidity determines the design temperature difference. Many years ago, there were many cold storage for storing flowers in Kunming City, Yunnan Province, but they were not very satisfactory, and the flower shop owner complained that the flowers couldn’t be storage well. What was the reason? Because contractors only focused on the temperature, but not humidity. To achieve the desired relative humidity, the temperature difference must be small enough; if a big temperature difference is designed, the relative humidity will be low(dry), because it is similar to a dehumidification process. It can also be understood from another aspect: why can the operating room have a temperature difference of 10 to 12°C? Because people are operating inside, and the human body is most comfortable with a relative humidity of 50% to 65%.

Here are 4 ranges of temperature differences that are sufficient to support most cold storage designs.

Level | Temperature Difference(℃) | Relative Humidity | The items stored and the type of storage |

1 | 4~5 | 90% | Unpackaged vegetables, Flowers, Ice cubes |

2 | 6~7 | 80%~85% | Packaged meat, Fish, Vegetables, Fruits. |

3 | 7~9 | 65%~80% | Potatoes, Onions, Melons and Packaged products for short-term storage. |

4 | 10~12 | 50%~65% | Preparation room, Separate room, Beer storage, Candy storage, Film storage. |

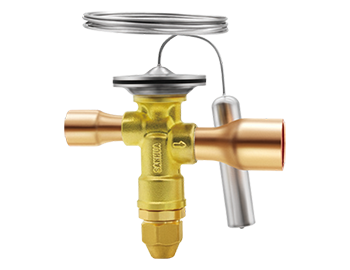

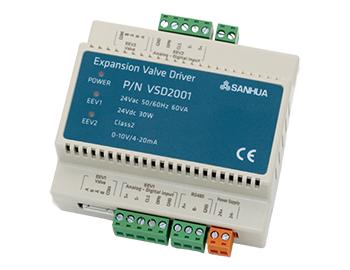

For example: If the cold storage requires -18°C and a mechanical load of 30KW, simply refer to the table to determine the design temperature difference. If the stored items are meat and fish, the temperature difference is -7°C; then the evaporation temperature is (-18) + (-7) = (-25)°C. Of course, the condensing type should also be considered, as there is a recommended condensing temperature based on the condensing type. This means that the cooling capacity of the machine with evaporation temperature of -25°C should be able to reach 30KW, which then determines the compressor selection. How to choose the other components? Select the evaporator based on the calculated cooling load, and then select the expansion valve according to the heat exchange capacity of the evaporator. Choose the condenser according to the refrigeration capacity of the compressor (for semi-hermetic or hermetic compressors, the motor power should be added). After the selection is completed, we also need to pay attention to the matching of the entire system and double check it.

Knowledge 3: How does big temperature difference happen ?

It is said that small and medium-sized cold storage has a high failure rate and big power consumption. After investigation, it was found that the root cause is "big temperature difference." The phenomenon of big temperature difference is basically caused by large compressors & small evaporators. In fact, the actual cooling capacity of a compressor is not the nominal power or theoretical discharge volume, but the mass flow rate, which refers to the amount of refrigerant transported into the expansion valve in the unit time through the liquid line. When the evaporator does not have the ability to vaporize all the mass flow output by the compressor, the expansion valve will be closed to reduce the flow sent to the evaporator, resulting in a decrease in the refrigeration capacity of the evaporator. At this time, the suction pressure of the compressor decreases, leading to a lower evaporation temperature. As the evaporation temperature decreases, the refrigeration capacity decreases, but the size of the cold storage does not decrease, and the heat of the items in the cold storage does not decrease. Therefore, the temperature inside the cold storage rises, forming a big temperature difference.

Therefore, larger compressors are not always better, and matching is the key. In many cases, more money is spent without achieving higher efficiency.

Knowledge 4: What will happen to the refrigeration system wtih a big temperature difference ?

We need to understand the chemical characteristics of the refrigerant. The lower evaporation temperature means higher discharge temperature. This phenomenon is more visible in R22 refrigerant. When the evaporation temperature falls below -20°C, the discharge temperature can suddenly rise to a very high level. Excessively high discharge temperatures lead to increased mechanical wear, which undoubtedly affects the service life of the compressor. In addition, at high discharge temperatures, the painting on the scroll compressor's shell will carbonize, the piston compressor's valve plate will accumulate carbon deposits, and the screw compressor's bearings will wear down eventually leading to the rotor becoming stuck. This is the first bad of big temperature differences: damage the compressor.

Secondly, big temperature differences cause the evaporator to frost too quickly and excessively, resulting in low efficiency of the refrigeration system. Measured data showing that in a semi-hermetic piston-type -18°C cold storage, when the temperature difference is 7K, the system's refrigeration capacity is 32.8KW. When the temperature difference is 10K, the refrigeration capacity decreases to 25.7KW, there is a reduction of about 22%. And when the temperature difference reaches 15K, the refrigeration capacity falls to only 18.4KW, almost half of the original amount.

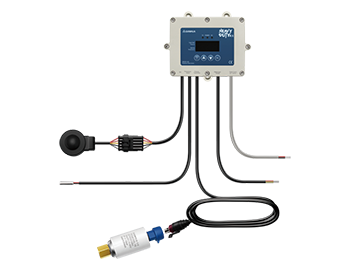

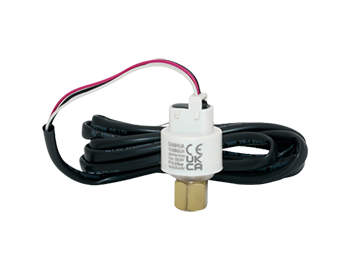

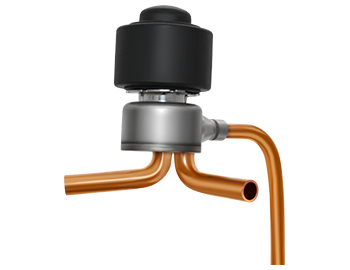

Topic 5: How to measure the actual temperature difference during the operation of the cold storage?

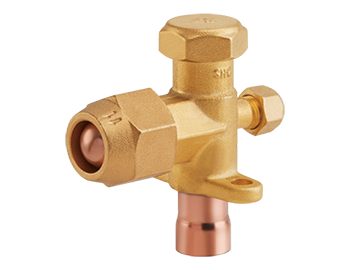

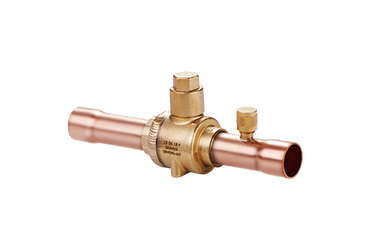

You can install a scharder valve at the outlet of the evaporator; It is recommended for both installers and air cooler manufacturers to have it. If you want to know the actual operating temperature difference of the cold storage you designed, use a 0.5-class precision pressure gauge, measure the pressure value at this location, and compare it with the corresponding temperature value, and the temperature difference is the difference between this temperature and the temperature displayed on the cold storage screen. Please note that the measurement should be taken at the outlet of the evaporator, not at the suction port of the compressor, because there is pressure drop in the suction line.