Sanhua has always been a pioneer in the field of flow control components, leading the industry trend with new materials and new processes. The substitution of steel and aluminum for copper/brass has always been a driving force for industry development.

From the outside, Sanhua's insisit with stainless steelization seems almost crazy, but there are many considerations behind it, which we call the "3 principles."

1. Lead-free

Currently, all the brass we use contains lead, which is a controlled hazardous substance in the EU RoHS regulation (>0.1%), but it has always been exempted (copper alloys with a density of less than 4%). In recent years, there have been voices calling for the cancellation of this exemption, so we have been asking internally: Can we achieve lead-free solutions for all product categories ?

2. Carbon Footprint

Do our solutions truly reduce carbon footprint? Not only in the product itself but also considering the processing and usage aspects. We focus on the full life cycle of carbon footprint.

3. Customer Value

If the solution cannot bring any value to the customer, we should not do it.

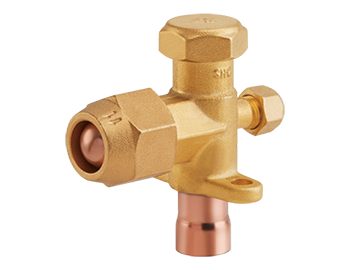

based on these 3 aspects, Sanhua has successfully stainless steelized a lot of products. Today, let's take a simple product as an example: ball valve.

Many people have seen how Sanhua has achieved stainless steelization for many complex products, and you might wonder, why hasn't anyone thought of stainless steelizing ball valves after so many years of using brass ones?

It's not that we haven't thought about it, but it's not as easy as it seems.

It's true that achieving simple stainless steelization is not difficult, someone could easily produce a stainless steel ball valve tomorrow. However, it's challenging to meet both the 2rd and 3rd principles mentioned above. If we only pursue stainless steelization to cater to this "trend" but consume more energies or use it as an opportunity to "disrupt the market price," It's not truly sustainable development.

Therefore, not all stainless steelization is worth doing.

Can we achieve lead-free solutions for every product category?

Can ball valves be done?

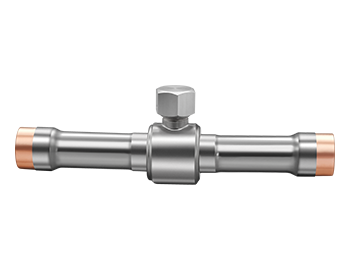

The development of the GBV stainless steel ball valve began with these questions every day.

We tried many ways but found that compared to brass valves, we consume more energy to produce them.

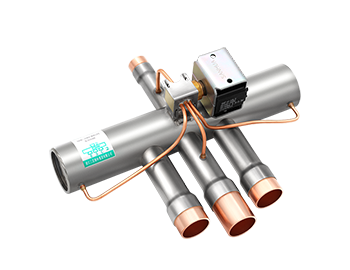

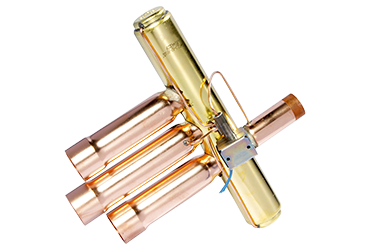

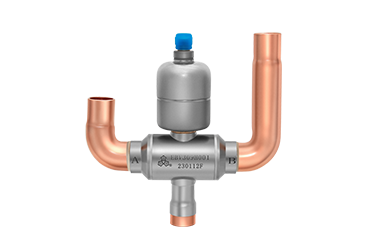

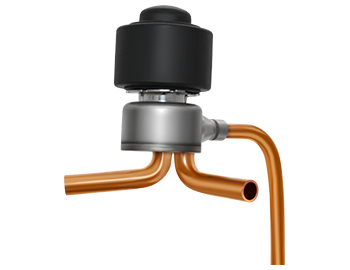

It wasn't until the birth of Sanhua EBV series electric ball valve that we found inspiration. The EBV is a combination of a step motor and a ball valve. From the valve bottom design, we came up with a creative solution. From one idea to another, the road suddenly became clear. When we simplified the GBV ball valve design, the entire production process also became very "low-carbon." Taking the 7/8” ball valve as an example, the GBV stainless steel ball valve has a nearly 45% lower carbon footprint throughout its entire lifecycle compared to the brass SBV.

So what other customer value does the GBV bring in the stainless steelization process?

Firstly, great truth in simple words is extremely reliable. As a ball valve, the primary demand is not to leak. The GBV ball valve uses laser welding and tunnel furnace brazing, greatly reducing the risk of external leakage at the joint. The sealing pads on both ends of the valve ball also suffer less deformation due to the smaller heat affected zone of laser welding, increasing the operating life (less wear) by more than 10 times.

Secondly, after stainless steelization, the ball valve becomes much lighter and much easier to fix. In the past, some scenes that required fixed plates can now be simply secured with two "clamps" or even been cancelled. This addresses a common issue caused by unreasonable fixing of ball valves in the past (the valve's own weight plus long-term system vibration fatigue).

Last but not least, although the GBV is lighter, it is stronger. We utilize the inherent high-strength characteristics of stainless steel to increase the design pressure of the standard ball valve to 49 bar.

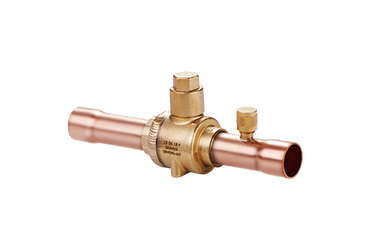

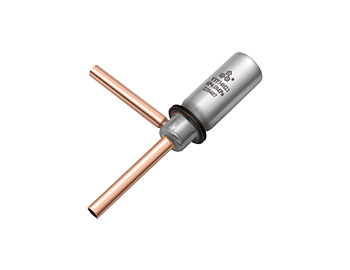

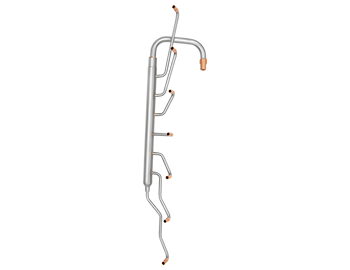

In addition, the GBV offers various sizes. The GBV will cover a size range from 5/8" to 1-5/8". The connections can be soldering or thread, or a combination of both. You can also choose whether to include a charging port.

The simplicity of the GBV ball valve you see today is the result of repeated comparison of more than a dozen processes and thousands of experiments in places where others think they can easily hide them. However, for Sanhua, all of this is worth it because we have been relentlessly pursuing customer value on the path of energy saving and environmental protection!