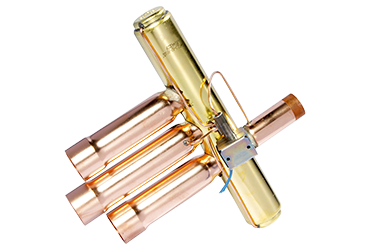

There is a common practice in the industry that when mentioning 5hp (used for air conditioning/heat pump) 4-way valves, people tend to assume SHF-20 type 4-way valves. However, such a usage actually involves considerable risks.

Firstly, the 5hp matched with the SHF-20 originated in the era of R22 refrigerant. However, nowadays the use of R410A is already very widespread. Although the capacity of the compressor is similar, the 4-way valve capacity has been greatly improved. While using R32, the 4-way valve capacity has increased by more than 50% compared to R22.

In other words: The 5hp system is still the same, but the SHF-20 is no longer the same.

Secondly, under low ambient temperature applications, the compressor's capacity has regressed instead of improving. Combining both aspects, the problem of oversizing has become quite serious. If the design of other aspects of the system is not appropriate, it may cause the clog(no-switching) of 4-way valve.

In other words: The SHF-20 is no longer the same, and the 5hp system is also different.

If you still don't understand the mechanism, you can go to Sanhua E-learning. You can review and learn from the first episode: Explaining the selection and control of 4-way valves.

- Director of 4-way valve Quality Department, Lv Yonggen -

The Director of 4-way valve Quality Department Lv Yonggen said: 'According to our continuous tracking of the 4-way valves failure in the market in recent years, 80% of the problems are due to non-switching issues, and a significant portion of this is caused by the oversizing of the valve.'

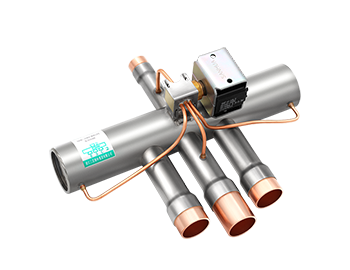

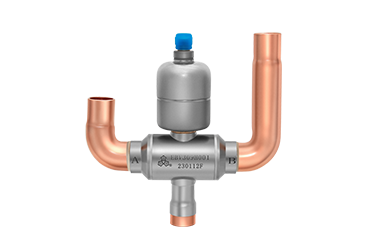

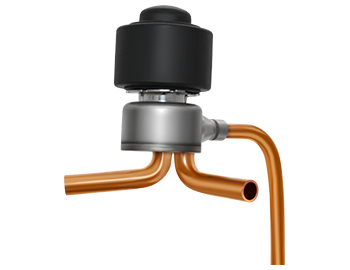

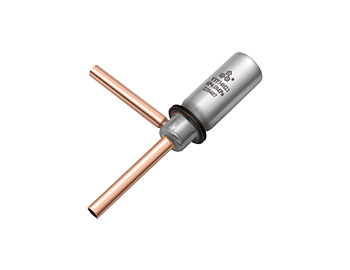

based on this, Sanhua launched the 20GR 4-way valve. We have redesigned the capabilities of the 20GR, and when applied to R410A or R32 air conditioning/heat pump systems, the 20GR can better match the 4-6hp systems.

Regarding the long-standing pain points in the industry, we hold great expectations for the 20GR. Therefore, from the initial design, engineers desired to incorporate numerous advantages into one. Let's take a closer look at them.

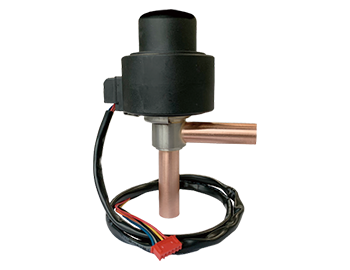

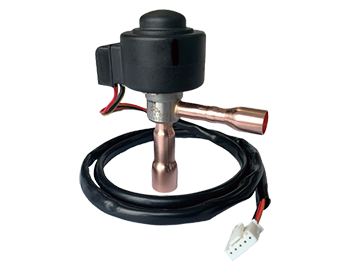

1. Universal model for both fixed and variable speed

- Product Line Manager of 4-way Valve , Zhu Yong -

The 4-way Valve Product Line Manager, Zhu Yong, said: 'The distinction between fixed and variable frequency 4-way valves has been around for a long time, and there has always been a demand for universal valves. However, we understand that it is difficult to achieve this goal without changing the system control logic. In the past, SANHUA has been committed to promoting the optimization of control logic, and we have now seen significant improved situation. We have never given up on the effort to merge two into one, and this goal will be first achieved in our 20GR product.'

Note: Intermediate flow refers to the flow rate from the discharge bypassed to the suction port during switching process.

If you still don't understand the mechanism, you can go to Sanhua E-learning and review the first episode: Explaining the selection and control of 4-way valves.

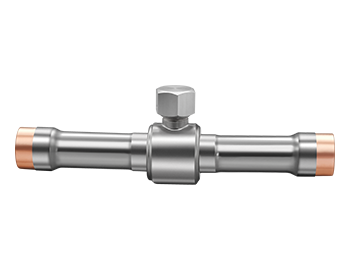

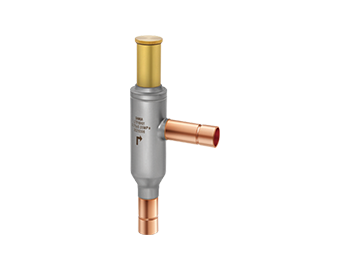

2. Full stainless steel design: More stable raw material costs, lower carbon footprint

The 20GR adopts an almost full stainless steel design, not only reducing the use of copper/brass materials but also meeting the lead-free requirements pursued by the European Union for many years. The product uses the most Eco-friendly process currently available from Sanhua, achieving low emissions and pollution during the manufacturing process.

- Director of 4-way valve Engineering Department, Wang Changdong -

Director of 4-way valve Engineering Department, Wang Changdong, said: 'According to our calculations, the production and use of each stainless steel 4-way valve like 20GR can ultimately lead to a reduction of about 48% in carbon emissions. When I realized that this work could make such a significant contribution to our living environment, we truly felt proud!'

Senior employee in the 4-way valve workshop: 'Watching the 'shining' products coming off the production line, with such perfect finishing, I have to say that I have been working on 4-way valves for a lifetime, but now I truly feel that we are producing artworks.'

3. High reliability

The 20GR has dozens of welding points that are welded together in a tunnel furnace at one time, ensuring that each welding material can penetrate fully and evenly, guarantee an extremely low external leakage risk.

The director of the 4-way valve quality department, Lv Yonggen, said: 'As we produce one million pieces of brass valves, we might find one with external leakage, but with stainless steel 4-way valves, this issue is almost zero.'

'We found that some brass 4-way valves leak after years of operation due to long-term fatigue vibration (system vibration), mainly caused by stress generated during the flame brazing process during valve production. The tunnel furnace process of 20GR effectively releases stress and controls this external leakage risk from the very beginning.'

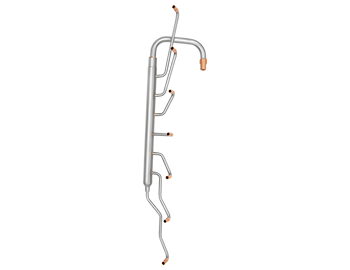

4. Easy installation and welding

Compared to the original brass SHF-20 4-way valve, the 20GR occupies less installation space, but the original system's piping length can remain unchanged. Even if using the original system's piping design, replacement can be easily achieved. The optimized copper connector design ensures the same welding behaviour as the brass valve but also effectively prevents excess solder from flowing into the 4-way valve interior.

This is the 20GR 4-way valve, which can better match the 4-6hp system and perfectly demonstrates the truth of 'buying the right instead of the expensive!'