As spring arrives and everything comes back to life, prices have risen across the board, especially copper prices which have skyrocketed. Consequently, the price of refrigeration valves, which use copper/brass as the main raw material, has also soared. However, amidst this wave of rising prices, there is a category of valves that remains "rock-steady" - stainless steel valves, which are the "in-thing" in today's era.

In fact, Sanhua had predicted this situation long ago and has repeatedly advocated the concept of 'less copper, copper-free, steel instead of copper, aluminum instead of copper, and even engineering plastics instead of copper' in public. At the same time, Sanhua has also practiced this concept in action, adopting stainless steel materials as much as possible in the research and development of our components.

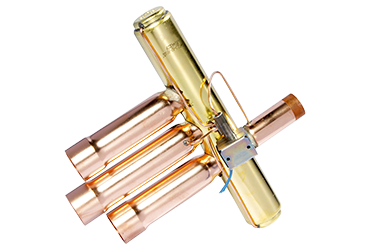

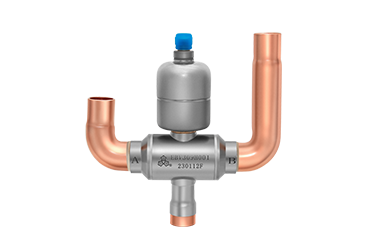

about 10 years ago, Sanhua launched its first "4KW stainless steel 4-way valve" for room air conditioning customers. Due to the lower heat loss of stainless steel compared to brass, the system energy efficiency was increased by 1%. Don't underestimate this 1%, thinking back to the past, it represented the highest honor of being a "leader in energy efficiency promotion."

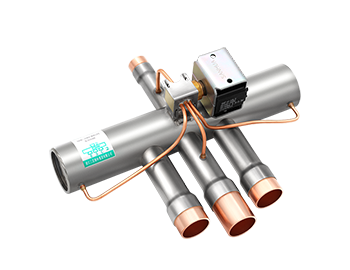

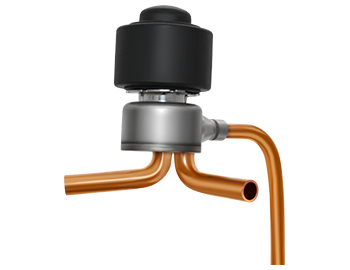

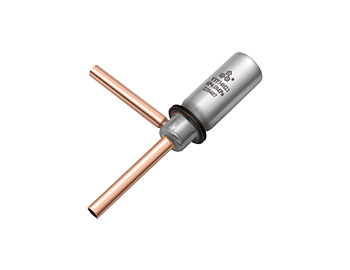

The picture shows the world's first mass-produced 4KW stainless steel 4-way valve.

You may had this question: Why didn't the stainless steel 4-way valve immediately expand to larger cooling capacity back then? Why did the Sanhua commercial stainless steel 4-way valve 'kept quiet down for so many years'?

There were actually reasons behind this. The price advantage of stainless steel raw materials is significant, but the processing difficulty is so great that it deters many people. It was indeed difficult to create more cost advantages for the stainless steel 4-way valve compared to the brass valve at that time. However, the R&D team of Sanhua never stopped studying the stainless steel technology.

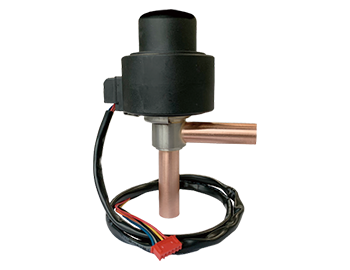

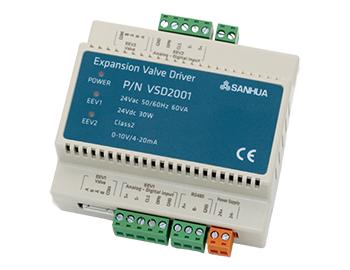

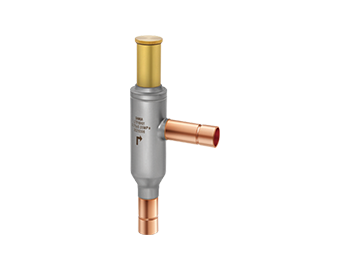

Therefore, they launched the VPF electronic expansion valve, which is a large-scale electronic expansion valve from 12.5 tons to 400 tons, featuring a full stainless steel valve body. The (steel-copper) bi-metal connection was also successfully developed and applied to the VPF, improving the efficiency of brazing.

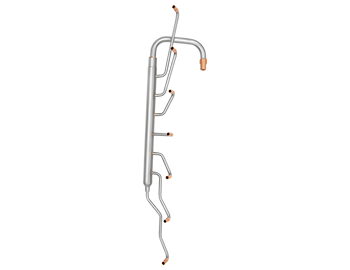

At the same time, stainless steel and aluminum pipe fittings have overcome various difficulties and opened up their own path for Sanhua pipe assembly, which is highly appreciated by customers. Suddenly, refrigeration systems equipped with stainless steel pipe fittings have become a symbol of high-end.

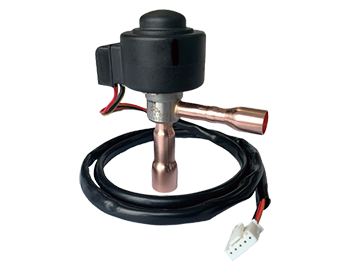

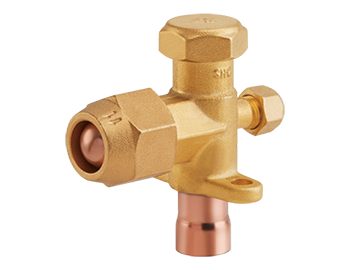

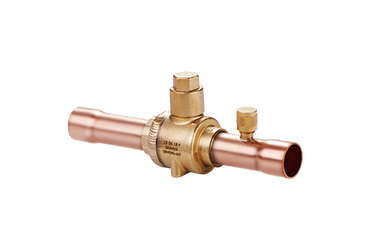

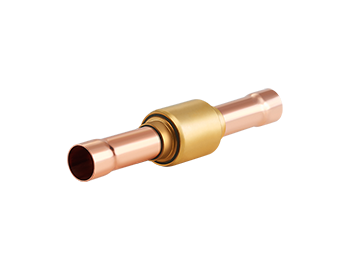

The success of VPF EEV and stainless steel pipe fittings is an important milestone in the application of stainless steel. Subsequently, Sanhua continued to launch the CCV series of diaphragm check valves. At that time, the homogenization competition in the market for this product was already quite fierce, and they were all made of copper. It was a challenge faced by Sanhua to 'make the difference'. Sanhua believes that if a product cannot create value for customers, it is better not to do it.

Thus, the stainless steel CCV diaphragm check valve was born, and the stainless steel models covered specifications from 3/4" to 1-5/8".

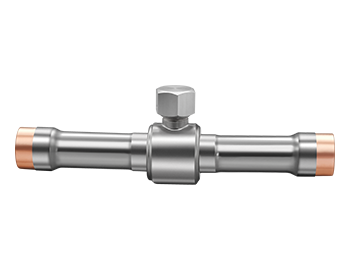

4 years ago, Sanhua believed it was the right time for the stainless steel 4-way valve to expand to larger capacity. This is because with the continuous exploration, study, and innovation of Sanhua team, our technology has now been able to solve the problems of the past.

This time, their goal was even greater... because we found that they have become more thorough in their stainless steel conversion. Remember earlier generations of stainless steel 4-way valves still had 4 copper connections, while the latest generation can be called "full stainless steel 4-way valves," leaving only a small section of copper pipe for brazing. Moreover, the pipe size design allows pin-to-pin replacement with brass valves, without changing the system piping.

Now, the Sanhua stainless steel 4-way valve family ranges from 4KW to 70KW, whether it's residential air conditioners, heat pumps, multi-split systems, or modular chillers, everyone can enjoy the benefits of this innovation.